The cost of choosing the wrong fastener: connection failure, assembly problems and extra costs

In mechanical assembly and CNC machining, the choice of fasteners directly affects the stability and long-term performance of the structure. The wrong fasteners may cause loosening, breakage, or even cause safety hazards, and the cost of subsequent repairs often far exceeds the initial investment of the correct choice.

Common fastener types and their application scenarios

The most commonly used fasteners in CNC machining include bolts, screws, rivets and anchors, each of which is suitable for different load conditions, environmental requirements and material combinations. For example:

Bolts: high-load removable connections ---------Screws: light fixing or precision assembly

Rivets: permanent high-strength connections--------Anchors: concrete or wall fixings

How to choose the most suitable fasteners?

When choosing fasteners, you need to consider the stress conditions, environmental factors (such as corrosion risks), material compatibility and installation methods. This guide will introduce the characteristics of various fasteners in detail to help you make the best decision.

What are fasteners?

Fasteners are common parts used to connect, fix or seal mechanical parts, such as bolts, nuts, screws and rivets, and are widely used in industrial manufacturing, construction and daily assembly.

Fasteners can establish permanent or temporary connections without damaging the connected parts.

Types of fasteners

Understanding the different types of fasteners is key to choosing the right solution for your application. Each fastener has a specific purpose, depending on its design, material, and the way it connects the parts.

Screws

A screw is a threaded rod that can be rotated into the material and fixed by itself. It does not require a nut and is widely used in machinery, electronics, construction and home assembly.

Bolts

It is a fastener with external threads, usually used in conjunction with nuts, and achieves high-strength detachable connections by tightening. It is widely used in machinery, construction and industrial assembly.

Nuts

It is an internally threaded fastener, usually used in conjunction with bolts or screws, and provides a stable and reliable connection by tightening. It is widely used in mechanical assembly, building structures and industrial equipment.

Washer

A washer is a flat ring-shaped fastener that is usually installed between a bolt/nut and a connector to disperse pressure, prevent loosening and shock absorption, or seal protection. It is widely used in fields such as machinery, automobiles, and plumbing engineering.

A rivet is a permanent mechanical fastener that fixes the connector by deformation. It is suitable for high-strength, non-detachable assembly scenarios (such as aviation, bridges, and steel structures).

Pin

Pin is a smooth or slightly grooved rod used to align or fix parts. They are often used in engines and gear systems. Pins are not threaded and are easy to insert or pull out. They help with positioning and rotation control.

Anchor

Anchor is a fixing device that provides stable force support by embedding or locking in the base material (such as concrete, rock). It is widely used in the fields of construction, shipbuilding, and mountaineering safety.

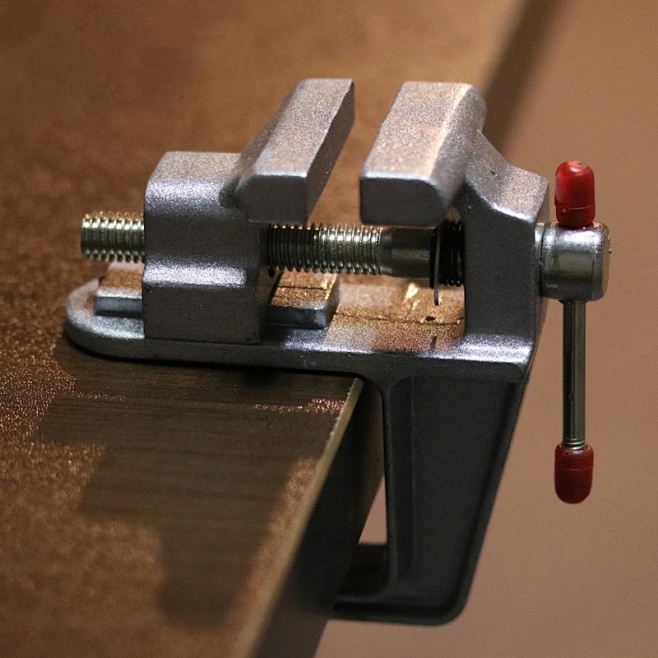

Clamp

A clamp is a mechanical device used to fix, position, or support a workpiece (such as a machine tool clamp), while a clamp is a tool that fixes an object by clamping force (such as a folder, spring clamp), both of which are widely used in manufacturing, woodworking, and daily scenes.

How to choose the right fastener?

Choose the type of fasteners (such as bolts, rivets or adhesives) with matching strength, corrosion resistance and size according to the force requirements, material properties, environmental conditions and installation methods

Start your custom fastener project at Wsrcnc - Get a quick quote

In CNC machining, the strength, precision and assembly quality of fasteners directly affect product performance. wsrcnc uses precision drilling, high-precision thread processing and professional surface treatment processes to ensure that each fastener fits perfectly, significantly improving product durability and aesthetics.

We provide a full range of fastening solutions:

Standard parts: screws/bolts/rivets/inserts

Customized service: design special specifications on demand

With mature experience of 25,000+ parts, the components we deliver can achieve high-quality direct assembly, helping you optimize production efficiency and product reliability.