The development of polycarbonate (PC) is a model of material science. As early as 1898, the prototype of this high-performance engineering plastic appeared. After more than half a century of technological accumulation, it was finally industrialized and patented by Bayer in 1953. Its excellent performance is mainly reflected in three aspects: extraordinary mechanical strength (impact resistance is 250 times that of ordinary glass), excellent optical transparency (light transmittance is 90%), and excellent processing performance (excellent adaptability to injection molding and CNC processing). It is this unique combination of properties that makes it the material of choice for demanding application scenarios such as automotive lighting systems, aviation transparent components, and high-end medical equipment, and it can still maintain stable reliability in extreme environments.

As a benchmark material in the field of engineering plastics, the excellent performance of polycarbonate (PC) has been fully verified in many demanding application scenarios. This article will deeply analyze the core technical points of polycarbonate processing, and systematically explain how to fully release the potential of materials by optimizing the manufacturing process, so as to create high-quality products that exceed industry standards in terms of performance, precision and reliability.

What is polycarbonate?

Polycarbonate (PC) is a high-performance engineering plastic, known for its excellent impact resistance, high transparency and heat resistance. It is known as the "steel in the plastic industry" and is widely used in automobiles, electronics, medical and other fields.

How is polycarbonate made?

Polycarbonate is mainly industrially produced by interfacial polycondensation or melt transesterification: the former reacts bisphenol A with phosgene in alkaline solution at room temperature to form a polymer, and the latter reacts bisphenol A with diphenyl carbonate in a high-temperature molten state. Both processes ultimately require post-processing such as pelletizing and drying to obtain transparent granular raw materials, which can be directly used for molding processes such as injection molding and extrusion. The carbonate group (-O-CO-O-) in its molecular chain gives the material unique toughness and thermal stability.

A brief history of polycarbonate processing

The history of polycarbonate processing began in the 1950s after Bayer achieved industrial production. In the early days, it was mainly injection molding and extrusion molding. In the 1960s, with the advancement of mold technology, it began to be used in car headlights and explosion-proof equipment; in the 1980s, the maturity of CNC precision machining technology made it shine in the electronics and medical fields; since the 21st century, with the emergence of new processes such as micro-foaming and 3D printing, polycarbonate processing has entered a new stage of high precision and lightweight, and the machining accuracy has been improved from the initial ±1mm to today's ±0.01mm, and the application field has continued to expand.

Can wsrcnc process polycarbonate?

wsrcnc can process polycarbonate, which is easier to process than many other plastics and has extremely high tolerance to various processing methods. This adaptability makes it an ideal choice for CNC milling, drilling, turning and other conventional machining operations. Its inherent properties (such as high impact resistance and thermal stability) help improve processing efficiency, enabling the manufacture of precision polycarbonate parts with excellent dimensional stability and transparency.

What is the processing process of polycarbonate?

1. Raw material pretreatment

Drying and dehumidification: drying at 80~120℃ for 4~6 hours (water content needs to be less than 0.02% to prevent high temperature hydrolysis)

Dyeing/modification: adding UV stabilizer (for outdoor use), glass fiber reinforcement (mechanical parts) or flame retardant (electronic parts)

2. Core processing technology

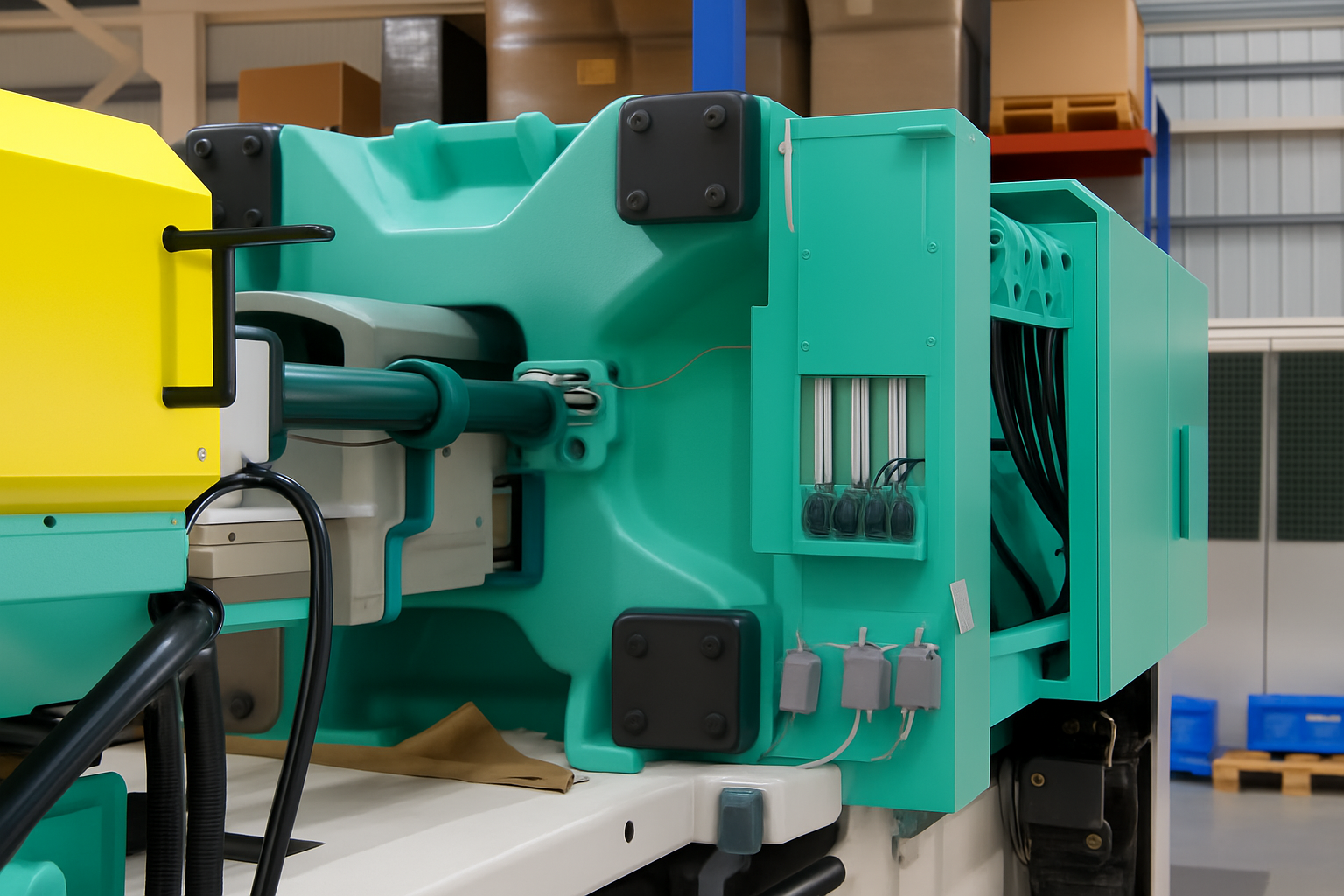

(1) Injection molding (accounting for 70%+)

Temperature control: barrel temperature: 260~320℃ (stage heating), mold temperature: 80~120℃ (reduce internal stress), high-pressure injection: pressure 70~150MPa, holding time adjusted according to wall thickness

Typical applications: mobile phone housing, car lampshade, medical equipment

(2) CNC precision machining

Tool selection: diamond coated tool (anti-melting sticking) Cutting speed: 200~400m/min (30% lower than metal) Cooling method: mainly air cooling (avoid stress cracking caused by water cooling) Applicable scenarios: small batch high-precision parts (such as optical frames)

(3) Extrusion molding

Temperature range: 230~300℃ (screw segment temperature control), molding products: plates, pipes (thickness 0.5~15mm), post-processing: online lamination (anti-scratch)

(4) Thermoforming

Sheet heating: 160~180℃ (softening and non-sticking to the mold) Vacuum adsorption: molding tolerance ±0.5mm (such as aircraft cabin interior panels)

3. Key process control points

Anti-degradation: melt residence time <8 minutes (easy to yellow above 300℃)

Stress control: annealing treatment (110℃×1h, eliminate internal stress)

Surface treatment: plasma spraying (improve coating adhesion) oxidation coating (wear resistance increased by 5 times)

4. Emerging processing technologies

Micro-foam injection molding: 15%~20% weight reduction, used for lightweight automotive parts

3D printing: use PC powder SLS process to manufacture complex topological structures

Laser welding: seamless bonding through infrared laser (medical equipment sealing)

What are the finishing options for polycarbonate processing?

The finishing options for polycarbonate mainly include: mechanical polishing (to achieve mirror effect Ra < 0.01μm), chemical polishing (using dichloromethane vapor treatment to improve transmittance), laser engraving (precision marking text or patterns), hardening coating (such as nano-silicon coating to enhance surface wear resistance), and ultrasonic cleaning (removal of micro-machining residues). For optical-grade applications, anti-glare (AG) or anti-reflection (AR) coating can also be performed to increase its transmittance to more than 92%. These processes can significantly improve the appearance, function and durability of PC products, and meet the surface quality standards of high-demand fields such as medical and electronics.

What are the key characteristics of polycarbonate that affect processing?

The core characteristics of polycarbonate processing include: high temperature sensitivity (melting temperature 260-320℃, easy to degrade overheating), hygroscopicity (need to pre-dry at 80-120℃ to water content <0.02%), high melt viscosity (need high pressure injection 70-150MPa), low thermal conductivity (key to control processing cooling rate) and significant rebound effect (CNC needs to compensate for 0.5-0.7% dimensional change). These characteristics require precise control of processing temperature, pressure and cooling rate to avoid silver streaks, stress cracking or optical distortion, especially in the production of precision parts (such as medical catheters, optical lenses). Strict process verification is required.

What tools are needed to process polycarbonate?

Processing polycarbonate (PC) requires matching professional tools according to the process: injection molding requires corrosion-resistant screw barrel (chrome plating) and mold temperature controller (temperature control ±1℃); CNC processing recommends diamond-coated tools (to reduce melt adhesion) and compressed air cooling system; thermoforming requires silicone vacuum grippers (to prevent surface scratches); surface treatment requires ultrasonic cleaning equipment and plasma spraying devices. Key auxiliary tools include: moisture meter (to ensure that the moisture content of raw materials is less than 0.02%), stress detector (polarized light observation of internal stress) and constant temperature oven (80-120℃ dehumidification), which together ensure the high precision (±0.05mm) and optical performance (transmittance>89%) of PC processing.

What are the application scenarios for processing polycarbonate?

With its high transparency, impact resistance and high temperature resistance, polycarbonate is widely used in the following high-end scenarios: automotive field (headlight lens, sunroof module, weather resistance and 30% weight reduction), electronic appliances (mobile phone housing, charger plug, flame retardant UL94 V0), medical equipment (surgical instruments, dialyzers, high temperature sterilization), aerospace (aircraft portholes, instrument covers, explosion-proof and UV-proof) and optical components (AR/VR lenses, light guide plates, transmittance>90%). Its easy processing (injection molding/CNC/extrusion) and surface coating characteristics have been extended to emerging fields such as new energy battery housings.

What are the advantages and disadvantages of processing polycarbonate?

Advantages: Polycarbonate has excellent processing performance, with high transparency (light transmittance > 90%) and super impact resistance (250 times that of glass), and can be formed into complex structures through various processes such as injection molding and CNC. It also has a wide temperature resistance range (-40℃~120℃), which is suitable for high-demand fields such as automobiles and electronics.

Disadvantages: It is easy to produce bubbles or silver streaks due to moisture absorption during processing (strict drying is required), it is easy to degrade and yellow at high temperatures (precise temperature control is required), and the surface hardness is low (Mohs hardness is about 3H), requiring additional coating to enhance wear resistance. In addition, the high viscosity of the melt requires high-pressure equipment (70-150MPa), which is costly.

What are the common problems and defects when processing polycarbonate?

1. Surface defects: Silver streaks (stress streaks) Cause: Water content in raw materials (>0.02%) or overheating of melt (>320℃) Solution: Pre-dry at 120℃ for 4 hours, reduce the temperature at the end of the barrel

Bubble/void Cause: Poor venting or insufficient pressure holding

Solution: Add venting grooves to the mold and extend the pressure holding time (+5 seconds for every 1mm wall thickness)

2. Mechanical performance problems

Cause of internal stress cracking: Too fast cooling rate or uneven demolding force

Solution: Control the mold temperature at 80~120℃, annealing treatment (110℃×1h)

Cause of brittle fracture: Material degradation or too high proportion of recycled materials (>30%)

Solution: Limit the melt residence time (<8 minutes), use fresh materials

3. Dimensional accuracy problems

Uneven shrinkage (tolerance exceeds ±0.1mm) Cause: wall thickness mutation or unreasonable cooling system design

Solution: optimize product design (uniform wall thickness), zone temperature control of mold temperature machine

Flash/burr Cause: insufficient clamping force or mold wear

Solution: increase clamping force (≥50MPa), repair mold parting surface

4. Processing defects

Melt fracture (shark skin phenomenon) Cause: injection speed is too fast or flow channel is too narrow

Solution: use hot runner system, reduce injection rate by 30%

Yellowing

Cause: overheating oxidation or UV exposure

Solution: add antioxidants (such as Irganox 1076), use UV stable grades

5. Defects Specific to CNC Machining

| Issue | Cause | Solution |

|---|---|---|

| Tool Adhesion | Heat accumulation | Use diamond-coated tools + air cooling |

| Rough Edges | Excessive feed rate | Reduce to 100–200 mm/min |

| Dimensional Rebound | Material elastic memory | Overcut compensation (0.3%–0.5%) |