What is CNC Machining? The Best Explanation for 2026 is Here!

You have a product idea. It could be a delicate component, a unique tool, or an innovative design that makes life easier. Perhaps you've already sketched it out or even completed a 3D digital model. Right now, you're thinking about how to bring your idea to life and turn your imagination into a physical object.

This is precisely where CNC machining shines. Whether you're an engineer, designer, entrepreneur, or anyone with a passion for creation, this guide will provide you with practical help. As a core technology of modern manufacturing, CNC machining can precisely and efficiently produce complex, durable, and fully functional parts without relying on mass production.

We will systematically analyze each step of CNC machining to help you make informed decisions. Through this article, you will clearly understand the basic concepts and operating principles of CNC machining. We will present it in simple and easy-to-understand language, avoiding complex jargon, striving to help you grasp the essence in one article.

We are Wsrcnc. For 15 years, we have been serving the automotive, aerospace, medical, and consumer electronics industries, providing high-quality parts manufacturing. We have accumulated extensive experience and established a trustworthy industry reputation in the rapid and precise delivery of customized parts.

What is CNC machining?

CNC machining is a precision manufacturing process controlled by computer programs. It utilizes preset digital instructions to drive machine tools to automatically perform operations such as cutting, drilling, and engraving on materials (such as metals, plastics, and wood), thereby transforming digital designs into physical parts.

How Does CNC Machining Work?

The working principle of CNC machining can be summarized as the process of "using digital instructions to drive machine tools, transforming virtual models into physical parts." It is, at its core, a highly automated subtractive manufacturing system.

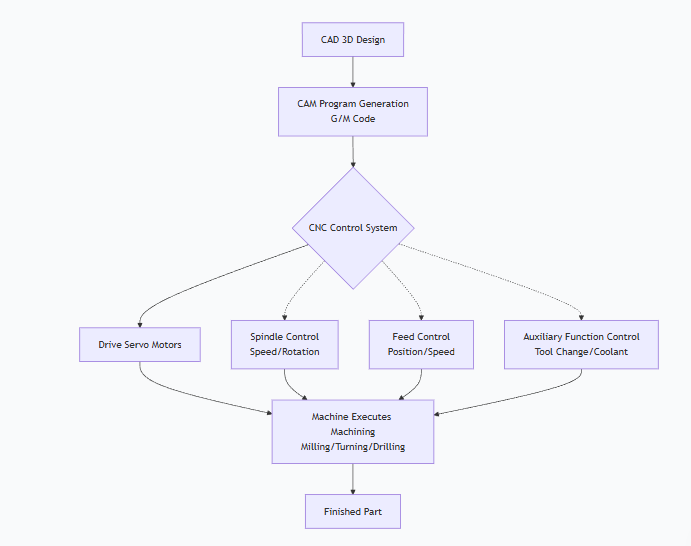

The following diagram illustrates the core workflow, helping you quickly grasp the overall process:

1. Detailed Core Principles

It is built on two pillars: Coordinate Motion Control and Programmed Instructions.

Coordinate Control:

All motion axes of the machine tool (e.g., X, Y, Z linear axes, A, B, C rotary axes) are equipped with servo motors.

The CNC system precisely controls these motors to move the cutting tool or workpiece to each programmed coordinate point in three-dimensional space.

Program-Driven Operation:

Every step of the machining process (where to go, how to move, how fast, how deep) is written into G-code (a standardized machine tool language).

The CNC system reads and interprets this code, converting it into electrical signals that command the coordinated movement of all motors.

2. Workflow Breakdown (Corresponding to the Diagram)

Create a 3D Model:

A designer uses CAD software to create a precise 3D digital model of the part. This is the "blueprint."

Generate the Machining Program:

Toolpath: The trajectory of the tool's center point.

Cutting Parameters: Spindle speed, feed rate, depth of cut.

Tool Selection and Tool Change Commands.

Auxiliary Commands like coolant on/off.

CAM software is used to translate the CAD model into G-code that the machine tool understands.

The programmer defines key parameters here:

Machine Setup:

The raw workpiece material (blank) is securely clamped to the worktable or chuck.

Appropriate tools are installed as per the program, and tool setting is performed—establishing the positional relationship between the tool and workpiece datum, which is then entered into the CNC system.

Execute Automated Machining (The Core Step):

Control Position: Drive servo motors to move the tool or workpiece precisely to target coordinates.

Control Motion: Move the tool along the defined path at the set speed.

Control the Spindle: Start/stop the spindle motor, control its speed and rotation direction.

Control Auxiliary Functions: Automatically change tools, activate coolant when needed.

The operator loads the G-code program into the machine's CNC Control System.

Upon start, the system interprets the code line by line and issues commands to:

The cutting tool progressively removes material from the blank according to the programmed instructions until the final part shape is achieved.

Post-Processing and Inspection:

After machining, the part is removed for cleaning and deburring.

Key dimensions are verified using tools like calipers or CMMs (Coordinate Measuring Machines) to ensure compliance with the drawing specifications.

3. Key Components

CNC Control System: The "brain" of the machine. Common brands include Siemens, Fanuc, and Heidenhain. It is responsible for interpreting code, calculating trajectories, and issuing control commands.

Servo Drive Unit: The "muscles" of the machine. Receives signals from the control system to drive the motors with precise movements.

Sensors & Feedback System: The machine's "sensory nerves." Monitors position, speed, load, etc., in real-time and feeds this information back to the CNC system, forming a closed-loop control to ensure accuracy.

An Analogy for Understanding

Think of CNC machining as an "Intelligent, Automated Engraving Machine":

CAD Model = Your beautifully designed sculpture blueprint.

G-code = The detailed, step-by-step engraving instructions written from that blueprint.

CNC Machine Tool = A tireless, perfectly obedient robotic sculptor.

CNC System = The robotic sculptor's brain, reading the instructions and commanding its hands.

Final Part = The completed physical sculpture.

How Wsrcnc Ensures Principles Translate into High-Quality Parts?

We understand the theory and excel in its application:

Design for Manufacturability (DFM) Optimization: Our engineers review your design before programming, suggesting optimizations for machinability, precision, and efficiency to prevent design flaws.

Precision Programming & Simulation: We use advanced CAM software to generate efficient and safe toolpaths, and perform virtual machining simulations to predict and prevent collisions or errors beforehand.

High-Precision Machines & Rigorous Calibration: We utilize high-performance 5-axis, mill-turn, and other CNC machines, adhering to strict periodic maintenance and precision calibration protocols to ensure our "muscles" are robust and reliable.

Full-Process Quality Control: From raw material inspection to in-process measurements and final inspection, key dimensions are monitored throughout, ensuring every delivered part precisely matches your digital model.

In summary, the working principle of CNC machining is the precise bridge between digital design and physical manufacturing. It transforms ideas into precise data commands, directing machine tools to perform reliable, repeatable, and precise movements, ultimately realizing the creation of physical objects from "0" to "1."

If you have specific design drawings or machining requirements, we can leverage these principles to provide you with a more targeted production process analysis and quote.