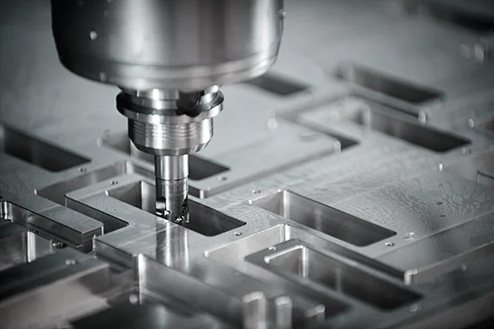

Complete Guide to Deep Cavity Machining: The Ultimate Solution to Vibration, Deformation, and Chip Evacuation

In the manufacturing of precision molds, aerospace components, and high-end medical devices, deep cavity machining remains a core challenge for CNC programmers and process engineers. When the cavity depth exceeds 3 times the tool diameter, or the aspect ratio is greater than 4:1, conventional machining methods become inadequate.

Imagine this: a tool "dancing" in a narrow, elongated space, the delicate balance between cutting force and rigidity, chips trapped at the bottom unable to escape, heat accumulating in a confined space... These are not just theoretical difficulties, but realities faced daily by every machine shop.

This guide provides a complete set of solutions for deep cavity machining, covering a comprehensive knowledge system from scientific tool selection, CAM programming strategies, cutting parameter optimization, to deformation and vibration control, helping you systematically conquer this manufacturing challenge.

What is Deep Cavity Machining? Why is it So Challenging?

Deep cavity machining specifically refers to the manufacturing process of cavities where the machining depth exceeds 3 times the tool diameter, or the aspect ratio is greater than 4:1. This is not simply "deep hole drilling," but a comprehensive test of tool rigidity, process strategy, and machine tool performance.

Core Physical Challenges of Deep Cavity Machining

Tool Rigidity Limit: When the length-to-diameter ratio (L/D) >3, tool stiffness decreases dramatically.

Chip Evacuation Dilemma: Chip accumulation in the confined space leads to recutting and temperature spikes.

Difficulty Delivering Coolant: Heat buildup in the bottom cutting zone cannot be dissipated in time.

Vibration Amplification Effect: The enclosed space acts as an acoustic resonance chamber, amplifying vibration exponentially.

Key Metrics for Assessing Deep Cavity Machining Difficulty

| Aspect Ratio | Difficulty Level | Recommended Strategy | Typical Applications |

|---|---|---|---|

| 3-5:1 | Moderate | Conventional Layer Milling | General Mold Cavities |

| 5-8:1 | High | Special Long-Flute Tools + High-Pressure Coolant | Automotive Molds |

| >8:1 | Very High | Plunge Milling + Special Toolpaths | Aerospace Structural Parts |

Complete Guide to Deep Cavity Machining Tool Systems

Tool Type Selection Matrix: From Roughing to Finishing

| Machining Stage | Recommended Tool Type | Core Advantage | Suitable Aspect Ratio | Typical Brand/Model |

|---|---|---|---|---|

| Roughing | Multi-Flute Corn Cob Mill | Efficient Chip Evacuation, High MRR | 3-6:1 | Sandvik CoroMill 316 |

| Semi-Finishing | Wavy/Milling Cutter | Vibration Damping Design, Moderate Rigidity | 4-8:1 | Kennametal HARVI Ultra |

| Finishing | Solid Carbide Long-Neck End Mill | High Precision, Excellent Surface Finish | 5-10:1 | OSG HY-PRO MILL |

| Ultra-Deep Cavity | Exchangeable-Head Long-Reach Mill | Cost-Effective, High Flexibility | 8-15:1 | Mapal MAPAL VariMill |

Performance Comparison of Different Tool Holders

| Holder Type | Radial Runout (μm) | Clamping Rigidity | Suitable Speed (RPM) | Deep Cavity Rating |

|---|---|---|---|---|

| Collet Chuck | 8-15 | ★★☆☆☆ | < 15,000 | Not Recommended |

| Side-Lock Holder | 10-20 | ★★★☆☆ | < 10,000 | Limited Use |

| Heat-Shrink Holder | 3-5 | ★★★★☆ | < 40,000 | Recommended |

| Hydraulic Holder | 2-4 | ★★★★☆ | < 30,000 | Highly Recommended |

| Shrink-Fit Holder | 1-3 | ★★★★★ | < 25,000 | Best Choice |

CAM Programming & Toolpath Strategies

CAM (Computer-Aided Manufacturing) Programming refers to the process of using software to convert a CAD model into G-code that a CNC machine tool can recognize. Programmers must plan efficient toolpaths based on part geometry, material, machine tool, and cutting tools.

Choosing the right toolpath is a systematic engineering task that requires weighing the following factors:

Part Geometric Features:

Steep vs. Shallow Areas: Use Z-Level machining for steep walls, and parallel or 3D offset strategies for flat areas.

Pockets vs. Bosses: Pay attention to plunge moves and chip evacuation for pockets.

Fillets & Corner Clearing: Select tools based on fillet radius and plan corner-clearing paths.

Material: Aluminum, Steel, Titanium alloy, High-Temperature Alloy, Composites? Different materials have vastly different machinability, affecting parameters and strategies (e.g., titanium favors small stepovers and greater depths of cut).

Machine Tool Performance: Machine rigidity, spindle power, speed, rapid traverse rates. Aggressive strategies are unsuitable for older or lighter machines.

Cutting Tools: Tool type (flat end mill, ball nose, corner radius), size, length, coating, number of flutes. The tool sets the lower limit, the strategy determines the upper limit.

Machining Stage:

Roughing: Core objective is Maximum Material Removal Rate (MRR). Strategies: Pocket Milling, Adaptive Clearing (Dynamic Milling), Trochoidal Roughing.

Semi-Finishing: Core objective is to create uniform stock allowance, providing stable conditions for finishing. Common strategies: Z-Level or Offset.

Finishing: Core objective is to achieve dimensional/geometric tolerance and surface quality. Choose the most suitable strategy based on surface shape (Parallel, Z-Level, Contour, Projection, etc.).

Corner/Floor Cleaning: Core objective is to remove remaining stock.

Efficiency & Cost: Shortest machining time vs. Tool life vs. Surface finish. An optimal balance must be found.

CAM Programming is the critical bridge transforming design into physical parts, and Toolpath Strategy is the steel framework of that bridge. An excellent CAM programmer is not just a software operator, but a Process Planner. They must deeply understand:

Geometry (Part Shape)

Physics (Material & Cutting Mechanics)

Machine Tool (Equipment Capability)

Cutting Tools

Strategy (Tactics within the software)

And they must find the optimal solution within these constraints. From basic 2.5-axis to complex 5-axis simultaneous machining, from dynamic milling for efficiency to streamline finishing for surface quality, the choice of strategy always serves one ultimate goal: To produce qualified parts with the lowest cost and shortest time, while ensuring quality and safety