Vacuum forming and injection molding are two widely used manufacturing processes for plastic parts. Both involve heating plastic and shaping it using a mold, the surface of which determines the part's geometry and can include design features such as draft angles, undercuts, ribs, and chamfers. However, these two processes differ significantly in several key aspects.

Vacuum forming and injection molding differ in design complexity, applicable materials, mold costs, production speed, and typical application areas. Generally, vacuum forming is more suitable for producing relatively simple, lightweight parts and is ideal for small-batch production; while injection molding can efficiently manufacture complex parts with fine details, and is particularly suitable for large-scale mass production.

The following sections of this article will provide a detailed comparison of vacuum forming and injection molding, analyzing their process characteristics, advantages, limitations, and practical application examples.

What is Injection Molding?

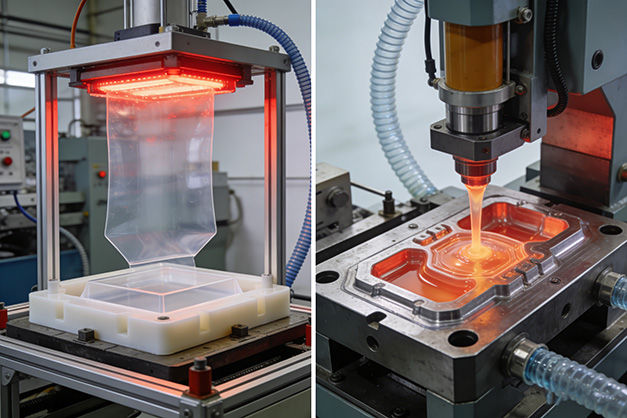

Injection molding is a manufacturing process that involves injecting molten plastic under high pressure into a pre-designed mold and allowing it to cool and solidify. First, plastic pellets are heated and melted in a barrel, then injected at high speed into the mold cavity through a pressurized nozzle. The high pressure ensures that the material fully fills every detail of the mold, accurately replicating the shape and texture of the cavity after cooling.

After molding, the mold is smoothly opened using mechanisms such as ejector plates, ejector pins, and sleeves to ensure the part is released intact. After the part is removed, further finishing processes such as trimming, sandblasting, or polishing are usually required.

Despite the numerous process steps, injection molding is extremely fast and highly repeatable. Automated injection molding machines can achieve up to 30 cycles per minute, making it particularly suitable for parts with complex structures, high precision requirements, and large-scale production needs, such as smartphone cases, electrical connectors, and medical device components.

Advantages of Injection Molding Compared to Vacuum Forming

Superior Design Capabilities and Precision

Complexity: Can mold extremely complex geometric shapes, including undercuts, threads, fine ribs, and snap-fit features (difficult to achieve with vacuum forming).

Precision and Consistency: Extremely tight dimensional tolerances and high repeatability, suitable for precision assembly.

Surface Quality: Directly replicates the mold surface finish, allowing for the production of parts with mirror-like or complex textured surfaces.

Excellent Material Properties and Versatility

Wide Range of Materials: Applicable to almost all engineering plastics (such as ABS, PC, nylon, POM), enabling the production of high-strength, heat-resistant, and chemical-resistant parts.

Homogeneous Parts: Uniform material density, isotropic physical properties, and high strength.

Extremely High Production Efficiency and Automation

Very short cycle times (usually tens of seconds), high degree of automation, suitable for ultra-large-scale production. Usually requires no trimming of flash, allowing for direct assembly and high integration.

Disadvantages of Injection Molding Compared to Vacuum Forming

Extremely High Initial Costs and Barriers to Entry

Mold Costs: Precision molds made of steel or aluminum are very expensive, with long design and manufacturing cycles (weeks to months).

Equipment Investment: Injection molding machines themselves are expensive.

Uneconomical for Small-Batch Production

Economical Batch Size: Due to the high amortization costs of molds and equipment, the unit cost for small-batch production is extremely high; typically tens of thousands of units or more are needed to be economical.

Inflexible Design Changes

Once the mold is made, modifying the mold design is costly and time-consuming, resulting in poor flexibility.

What is Vacuum Forming?

Vacuum forming, also known as thermoforming, is a manufacturing process that involves heating a plastic sheet until it softens, then using vacuum pressure to draw it against a single-sided mold surface. After cooling, a three-dimensional part is formed.

Advantages of Vacuum Forming over Injection Molding (i.e., disadvantages of injection molding)

Extremely low mold cost and development cycle: Molds are typically single-sided aluminum or resin molds, costing only one-tenth or even less than injection molds, and are quick to produce (a few days).

Ideal for small-batch production: Very suitable for prototyping, trial production, and small-batch customized products (tens to thousands of pieces).

Suitable for large, thin-walled parts: Can economically produce very large parts (such as car interior panels, bathtubs, boat hulls), which are difficult to achieve with injection molding.

Disadvantages of Vacuum Forming compared to Injection Molding (i.e., advantages of injection molding)

Design limitations: Can only produce shell-like and groove-like parts; difficult to create true three-dimensional structures, side holes, and precise details. Wall thickness uniformity is poor (thinner at corners).

Material and performance limitations: Primarily uses sheet materials, limiting material choices (mostly ABS, PVC, PC, PP sheets). Part strength is lower, mostly thin-shell structures.

Lower degree of automation and efficiency: Usually relies more on manual operation (such as material loading and trimming), resulting in longer production cycles (several minutes) and significant post-processing (trimming) work.

Main Differences between Vacuum Forming and Injection Molding

Vacuum forming and injection molding are two distinctly different plastic processing techniques. Their core differences can be clearly presented from the following six dimensions:

| Comparison Dimension | Vacuum Forming | Injection Molding |

|---|---|---|

| Core Principle | Physical Forming: Heated plastic sheet is shaped using vacuum suction to conform to a single-sided mold. | Fluid Injection: Molten plastic is injected under high pressure into a closed two-part mold cavity. |

| Mold | Single-sided mold (male or female), typically made of aluminum, resin, or wood. | Two-part closed mold (moving and fixed plates), made of high-strength steel or aluminum. |

| Cost Structure | Very low mold cost (typically 10%-20% of an injection mold), short lead time (days). Higher per-part cost. | Very high mold cost, long lead time (weeks to months). Very low per-part cost (at high volumes). |

| Design Capability | Limited: Suitable for large, thin-walled parts. Cannot form complex 3D structures (e.g., undercuts, threads). Uneven wall thickness (thinner at corners). | Extremely Strong: Can form highly complex 3D parts (with threads, snap-fits, precision gears). Uniform wall thickness. Excellent detail replication. |

| Materials & Performance | Primarily uses thermoplastic sheets (e.g., ABS, PVC, HIPS), limited selection. Finished parts are thin-walled shells with lower strength. | Can use most thermoplastic/thermoset plastic pellets, including high-performance engineering plastics. Finished parts are solid, with high strength and consistent properties. |

| Production & Economics | Low Speed: Longer cycle time (minutes), lower automation, more post-processing (trimming). Ideal for low volume, prototypes, large parts. | High Speed: Short cycle time (tens of seconds), fully automated, minimal post-processing. Optimized for very high-volume production. |

Summary and Selection Recommendations

Choose injection molding when: You need millions of highly complex, precise, and high-strength parts, and can tolerate high upfront mold investment and longer development times. Typical applications: mobile phone cases, gears, medical syringes, Lego bricks.

Choose vacuum forming when: You need hundreds to thousands of relatively simple, large, thin-shell parts, prioritizing low-cost molds and quick market entry, and where precision and strength requirements are not extreme. Typical applications: product packaging trays, refrigerator liners, car door panels, outdoor signs.