When the market is hotly discussing Xiaomi SU7, industry pioneers have begun to lay out the 2025 strategic model - YU7 SUV

When this future chariot is still in the blueprint stage, a key issue has emerged: how much investment is needed to build a prototype or core verification parts for it?

But "What is the price of YU7 parts?" is not a simple cost inquiry - behind this is a strategic game about R&D efficiency, risk control and resource allocation. In the critical transition period from concept to mass production of YU7, the process selection and manufacturing cost of each verification component will directly affect:

Can the R&D cycle be compressed by more than 30%?

How to avoid the risk of tens of millions of mold investment in the verification stage?

How to balance short-term verification and long-term mass production needs in budget allocation?

Price is just an appearance, the core proposition is:

▌ How to choose the optimal manufacturing process combination at each key node in the life cycle of YU7? (such as 3D printing fast iteration vs mold small batch verification)

▌ How to achieve through process innovation:

✓ Reduce the cost of the first round of samples by 50%+

✓ Increase the response speed of design changes by 2 times

✓ Maximize the smoothness of mass production transition

This directly determines whether Xiaomi can accurately launch this future SUV into the market window period with the lowest risk + optimal cost. We suggest starting from the full life cycle cost model and deconstructing the deep logic of "manufacturing process-R&D efficiency-commercial return" for analysis.

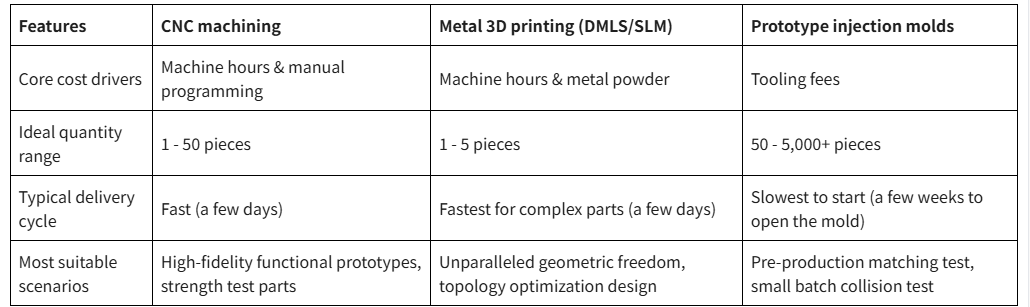

Comparison of cost and delivery time of three parts manufacturing methods of Xiaomi YU7

In order to make it more direct for everyone to watch, we first use a table to tell the comparison of different processes of Xiaomi YU7.

Why discuss the YU7 that has been launched on the market-the dark horse in the automotive industry

Xiaomi YU7 has been on the market for fifteen days, and the popularity has not diminished. Especially during the press conference on June 26, the order volume of Xiaomi YU7 has increased rapidly, and the large order exceeded 200,000 units in 3 minutes after the sale. It once became an absolute dark horse of new energy vehicles.

Its manufacturing cost and pricing strategy have attracted much attention. According to multiple cost analyses of Xiaomi SU7 Ultra, it can be confirmed that its manufacturing costs are mainly concentrated in multiple aspects such as batteries, power systems, smart hardware, lightweight materials, and technology research and development. These high-performance components significantly increase the manufacturing cost of the entire vehicle, and further reflect Xiaomi's investment in technology.

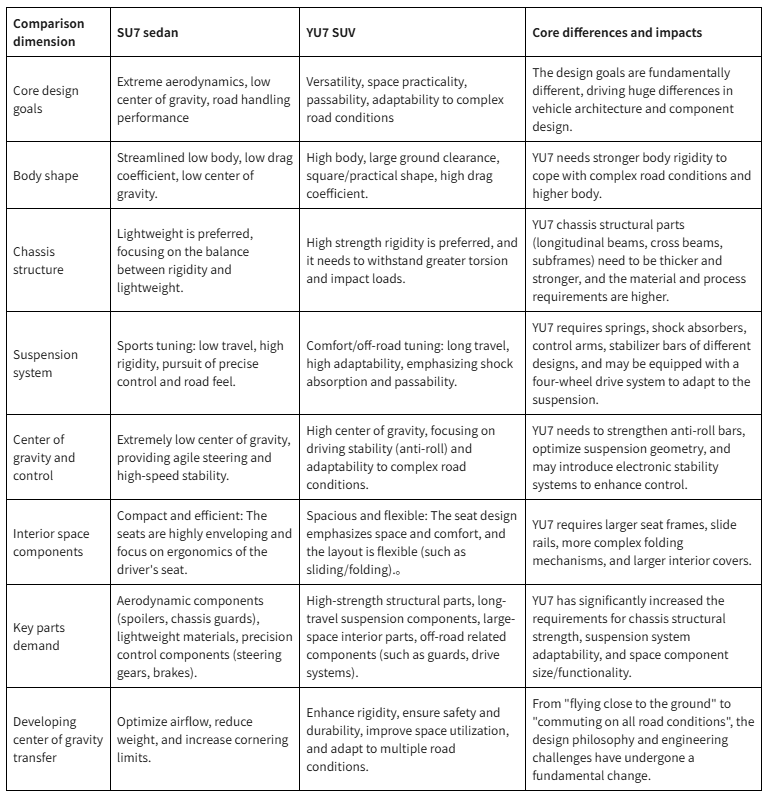

What are the differences between the core designs of Xiaomi SU7 and YU7?

Xiaomi YU7 core cost factor 1

Material selection is the core cost driver of the product, which directly affects:

Raw material cost: The unit price of different materials varies greatly (such as titanium alloy>>aluminum alloy>steel).

Processing cost:

Difficulty: Difficult-to-process materials (titanium alloy, high-strength steel, high-fiberglass plastic) require expensive equipment, slow processing speed, durable tools, and high cost. Easy-to-process materials (ordinary aluminum alloy, ABS) are efficient and low cost.

Forming/connection: Material properties affect process complexity and equipment investment (for example, ultra-high-strength steel requires hot forming).

Scrap rate: Difficult-to-process materials are more prone to defects, which increases costs.

Post-processing: Metals often require heat treatment/rust prevention, and plastics may require annealing/surface treatment, which will increase the process and cost.

Molds/Equipment: High-performance materials require higher-specification and more durable molds and equipment, with larger initial investments.

Xiaomi YU7 car material cost analysis:

1. Metal structural parts (high strength, lightweight demand)

① Aluminum alloy (battery pack/body structure)

Process: high pressure casting/extrusion molding/CNC processing

Typical products: battery housing, motor bracket, door anti-collision beam

Purpose: lightweight (40%+ weight reduction compared to steel), improved endurance

② Ultra-high strength steel (safety structural parts)

Process: hot stamping molding (HFQ)/laser welding

Typical products: A/B column reinforcement plate, chassis longitudinal beam

Purpose: collision safety (tensile strength 1500MPa+)

③ Magnesium alloy (extreme weight reduction parts)

Process: die casting/semi-solid molding

Typical products: seat frame, steering knuckle

Purpose: 30% weight reduction compared to aluminum alloy, but high cost

2. Composite materials (appearance/functional parts)

① Carbon fiber reinforced plastic (CFRP)

Process: hot press molding/ RTM (resin transfer molding)

Typical products: hood, rear wing, interior trim

Purpose: weight reduction of 50%+, high-end vehicle exterior parts

② Glass fiber reinforced plastic (GFRP)

Process: compression molding / SMC (sheet molding compound)

Typical products: battery pack cover, wheel arch

Purpose: low-cost lightweight solution

3. Plastic parts (interior / functional parts)

① Engineering plastics (high temperature / wear resistance)

Process: injection molding (hard mold / soft mold)

Typical products: instrument panel frame, door handle, charging port cover

Purpose: integrated molding of complex structures

② Elastomer (sealing / shock absorption)

Process: two-color injection molding / liquid silicone (LSR) molding

Typical products: door seals, battery cushions

Purpose: waterproof / shock absorption needs

4. Rapid verification process (sample development stage)

① Metal 3D printing (SLM / DMLS)

Typical products: special-shaped cooling water channels (motor housing), topology optimization bracket

Purpose: rapid verification of complex structures (72-hour delivery)

② Nylon 3D printing (SLS)

Typical products: intake manifold, interior functional parts

Purpose: mold-free functional testing

③ CNC rapid prototype

Typical products: steering knuckle, transmission gear

Purpose: high-precision metal parts verification

5. Mass production process (cost-sensitive parts)

① Integrated die casting (rear floor/front cabin)

Typical products: large body assembly (Tesla-style structure)

Purpose: reduce 200+ welding points and reduce costs by 40%

② Precision stamping (steel/aluminum plate)

Typical products: car door/fender/battery shell

Purpose: large-scale low-cost production

③ Injection hard mold (plastic parts)

Typical products: lampshade, button panel

Purpose: unit cost reduced to 1/3 of injection soft mold

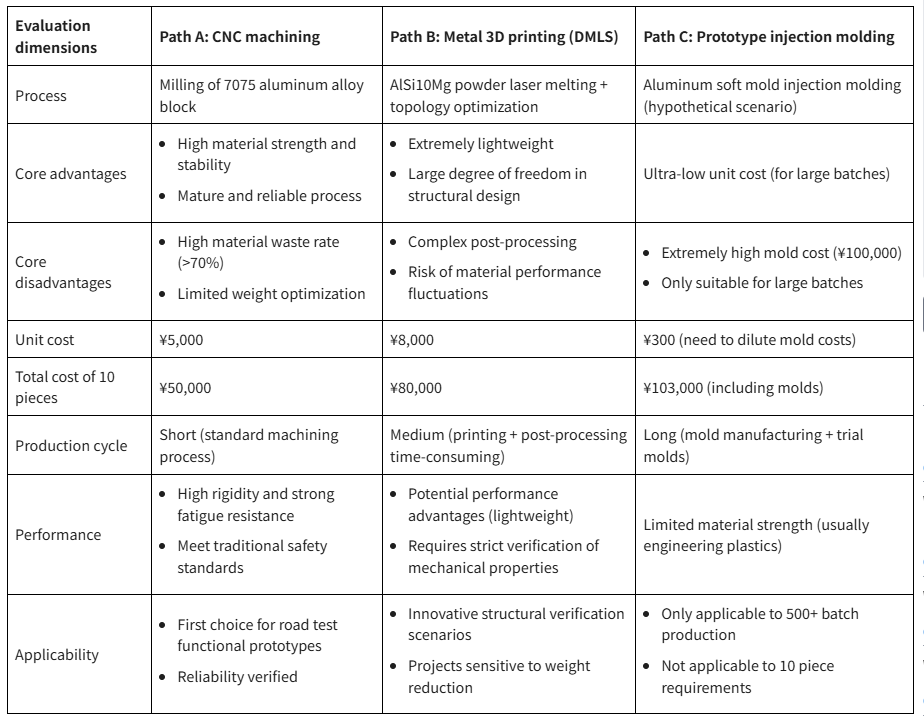

Xiaomi YU7 suspension control arm cost?

Goal: produce 10 fully functional YU7 rear suspension control arms for early road testing.

Hidden cost: beyond the price of each component

When evaluating the cost of parts, the surface unit price is just the tip of the iceberg. Ignoring hidden costs will lead to out-of-control total cost of ownership.

I: DFM analysis: the source of cost control

(1) Value: optimize design manufacturability in advance to avoid mass production traps.

(2) Hidden cost drivers:

Overdesign: deep holes, extremely small internal fillets, and unconventional wall thicknesses greatly increase processing difficulty and scrap rate.

Unnecessarily strict tolerances: forced use of high-precision equipment and additional testing will increase costs exponentially.

Material process mismatch: increase processing difficulty or post-processing costs.

(3) Action points: collaborate with DFM as early as possible to balance functionality and manufacturing economy.

Post-processing: a "cost black hole" that cannot be underestimated

(1) Core links: surface treatment, heat treatment, deburring, assembly, etc.

(2) Key cost factors:

Surface treatment: anodizing (type/film thickness/color/masking complexity), painting (special color/masking/environmental protection).

Heat treatment: process selection (such as vacuum), deformation control requirements. Deburring: Precision parts require automated processes (electrolytic/thermal deburring), and labor costs are high and unstable.

Assembly: Customized tools, testing and labor costs.

(3) Action points: Clarify and quantify all post-processing requirements (such as Pantone color numbers, burr standards).

III. Logistics packaging: the "armor" of precision parts costs

(1) Risk points: Quality and after-sales costs caused by transportation damage.

(2) Hidden investment:

Customized shockproof lining (EVA/blister tray).

Special protection such as anti-static (ESD) and moisture-proof (vacuum/desiccant).

Initial investment in turnover packaging.

(3) Action points: Jointly develop cost-effective protection plans based on the characteristics of the parts and the transportation environment. Decisions must be based on total cost of ownership

True cost = explicit unit price + DFM optimization cost + post-process cost + protective packaging cost + quality risk cost.

Simply comparing unit prices may lead to subsequent cost overruns, delivery delays and quality risks. It is recommended to adopt a total cost framework to evaluate the plan. We will help you analyze the hidden links item by item and optimize the overall cost

structure.

FAQ

Q: How much can the cost of Xiaomi YU7 parts be reduced after mass production?

A: The cost reduction in the mass production of YU7 parts depends on the order size, material utilization rate and production process optimization. Through large-scale production (integrated die casting, hard mold injection molding and other processes) and material optimization, the comprehensive cost of Xiaomi YU7 parts can be reduced by 30%~50% after mass production, of which the structural parts can be reduced by more than 40%, and the plastic parts can be reduced by about 60%.

Q: Why is 3D printed prototype sometimes more expensive than CNC processing?

A: 3D printed prototypes are more expensive mainly because of the high cost of special materials (such as metal powder is 3-5 times more expensive than blanks), high equipment depreciation costs (industrial-grade printers cost 300-800 yuan per hour), complex post-processing (accounting for 40% of the cost), and low material utilization (only 60-80%) caused by the design of support structures, while CNC processing material utilization can reach 90% and the working hours are shorter.

Q: At what stage should I consider opening a "soft mold" for prototype injection molding?

A: When 50-500 functional samples need to be verified, test assembly or small batch trial production is required, when 3D printing cannot meet the material performance requirements and the hard mold cost is too high (saving 60% mold fee), soft mold injection molding with a life of about 10,000 times should be considered.

Q: What documents do I need to provide to get an accurate quote for YU7 parts?

A: To obtain an accurate quote for YU7 parts, please provide: 3D drawings (STEP/IGS format), material specifications, process requirements (such as surface treatment), quantity requirements and acceptance criteria (such as dimensional tolerances), and indicate whether additional services are required (such as DFM analysis or secondary processing)